Understanding Chlorhexidine: A Critical Overview for B2B Applications

Chlorhexidine is a powerful broad-spectrum antimicrobial agent widely utilized across numerous industries for its efficacy in disinfection, antisepsis, and preservation. As a biguanide compound, it exhibits bacteriostatic and bactericidal properties against a wide range of gram-positive and gram-negative bacteria, fungi, and some viruses. Its versatility makes it indispensable in healthcare, pharmaceuticals, veterinary medicine, and various industrial applications where microbial control is paramount. This detailed overview delves into its manufacturing, technical specifications, application trends, and strategic considerations for B2B procurement and implementation.

Manufacturing Process Flow of Chlorhexidine

The synthesis of Chlorhexidine involves a sophisticated multi-step chemical process, ensuring high purity and consistent quality essential for its critical applications. Our manufacturing adheres to stringent international standards, including ISO 9001:2015 for quality management and ISO 14001:2015 for environmental management, guaranteeing a product that meets global regulatory requirements. The primary raw materials typically include 4-chloroaniline, dicyandiamide, and hexamethylenediamine.

Key Stages of Synthesis:

-

Stage 1: Intermediate Synthesis (Biguanide Formation)

Dicyandiamide is reacted with 4-chloroaniline hydrochloride under controlled temperature and pressure in an appropriate solvent (e.g., n-butanol or similar organic solvents). This reaction forms an intermediate biguanide derivative, typically 1-(p-chlorophenyl)-5-biguanide. This step requires precise temperature control (e.g., 100-140°C) and reaction time to optimize yield and minimize by-product formation. The purity of the raw materials is crucial here, as impurities can lead to side reactions and a lower-quality final product. This stage often involves sophisticated reactor systems capable of maintaining stable conditions, similar to those used in fine chemical synthesis.

-

Stage 2: Dimerization Reaction

The intermediate biguanide is then reacted with hexamethylenediamine. This is the critical dimerization step where two biguanide units are linked by the hexamethylene bridge, forming the crude Chlorhexidine base. This reaction typically occurs at elevated temperatures (e.g., 150-180°C) and may require a catalyst to facilitate the condensation. The choice of solvent and pH control during this stage are vital to ensure the correct molecular structure and prevent degradation or polymerization, which could impact efficacy and stability. This process often leverages advanced chemical engineering techniques to manage exothermic reactions and ensure uniform mixing.

-

Stage 3: Purification and Salt Formation

The crude Chlorhexidine base is highly insoluble in water and must be converted into a more soluble salt form for practical applications. Common forms include digluconate, diacetate, or dihydrochloride. The purification typically involves multiple recrystallization steps using specific solvents to remove unreacted starting materials, by-products, and other impurities. Following purification, the base is reacted with an appropriate acid (e.g., gluconic acid for digluconate) to form the desired salt. This step is meticulously controlled to ensure specific salt stoichiometry and crystal morphology. Filtration, washing, and drying follow to yield the final product. Quality control during this phase includes HPLC analysis for purity, heavy metal analysis, and microbial testing.

-

Stage 4: Quality Assurance and Packaging

Each batch undergoes rigorous testing to meet pharmacopoeial standards such as USP, EP, and BP. Key parameters tested include assay, impurities profile, pH, specific gravity (for solutions), heavy metals, microbial limits, and related substances. Packaging is conducted in controlled environments to prevent contamination and ensure product stability during storage and transit. Typical packaging includes HDPE drums or custom-designed containers, ensuring integrity and compliance with transport regulations.

Target Industries & Advantages: Our Chlorhexidine products are integral to the petrochemical industry (as a biocide in water treatment systems), metallurgy (for corrosion inhibition), and critical water supply & drainage applications (disinfection). Our manufacturing process emphasizes energy efficiency and closed-loop systems to minimize environmental impact, demonstrating advantages such as energy saving and superior corrosion resistance due to its controlled release properties when formulated appropriately.

Industry Trends and Market Dynamics

The market for Chlorhexidine is experiencing sustained growth, driven by increasing awareness of hygiene, expansion of the healthcare sector, and demand for effective antimicrobial solutions in industrial settings. Current trends indicate a shift towards higher purity grades for pharmaceutical and medical device applications, as well as the development of novel formulations (e.g., sustained-release coatings, combination therapies). The global chlorhexidine market size was valued at approximately USD 200 million in 2022 and is projected to reach over USD 300 million by 2030, growing at a CAGR of 5-6% [1]. This growth is particularly notable in emerging economies where healthcare infrastructure is expanding rapidly. There is also an increasing focus on environmentally friendly synthesis methods and more biodegradable formulations.

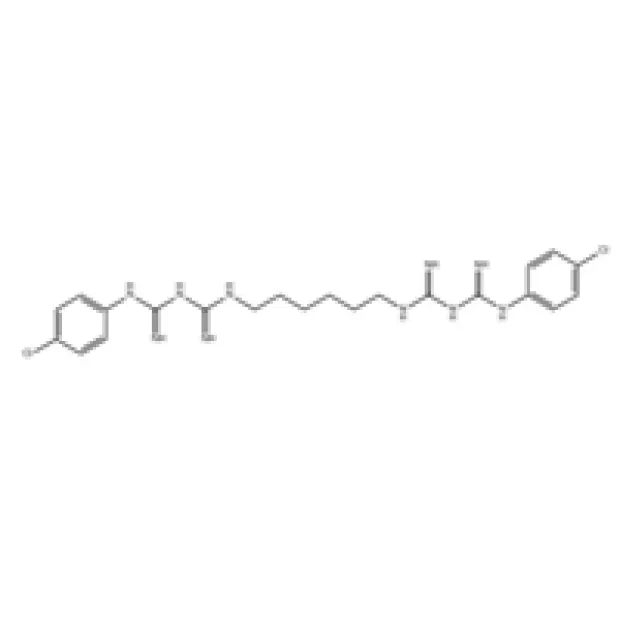

Figure 1: Typical appearance of Chlorhexidine (image for illustration).

Technical Specifications and Performance Parameters

Our Chlorhexidine products are engineered to meet stringent technical specifications, ensuring superior performance and reliability. The specific parameters vary based on the salt form (digluconate, diacetate, dihydrochloride) and concentration (e.g., 20% solution, powder).

Chlorhexidine Digluconate 20% Solution (Typical Specifications)

| Parameter | Specification (USP/EP Grade) | Method |

|---|---|---|

| Appearance | Clear, colorless to pale yellow, slightly viscous liquid | Visual Inspection |

| Assay (as Chlorhexidine Digluconate) | 19.0% – 21.0% w/v | HPLC |

| pH (1% solution) | 5.5 – 7.0 | Potentiometry |

| Specific Gravity (20°C) | 1.06 – 1.08 g/mL | Pycnometer |

| Related Substances (Total) | NMT 2.0% | HPLC |

| Heavy Metals | NMT 10 ppm | ICP-MS |

| Microbial Count (Total Aerobic) | NMT 100 CFU/mL | USP <61> |

| Endotoxin Level | < 0.5 EU/mL | LAL Test |

These specifications ensure that our Chlorhexidine meets the rigorous requirements for pharmaceutical ingredients, medical device disinfectants, and high-purity industrial biocides. Our products are regularly audited by third-party certification bodies, confirming adherence to FDA and EMA guidelines where applicable for specific grades.

Application Scenarios and Technical Advantages

Diverse Applications

- Medical & Pharmaceutical: Used in surgical scrubs, oral rinses, wound dressings, and as a disinfectant for medical devices. Its persistent antimicrobial action is highly valued.

- Veterinary: Integral to animal wound care, surgical antisepsis, and teat dips to prevent mastitis.

- Cosmetics & Personal Care: An effective preservative and antimicrobial agent in various cosmetic formulations.

- Industrial Biocides: Employed in water treatment systems, cooling towers, and pulp & paper manufacturing to control microbial growth, prevent biofilm formation, and mitigate bio-corrosion.

- Food & Beverage: Used as a disinfectant for surfaces and equipment, ensuring hygiene compliance.

Technical Advantages

- Broad-Spectrum Efficacy: Effective against a wide range of microorganisms, including gram-positive and gram-negative bacteria, fungi, and some viruses, crucial for comprehensive microbial control.

- Substantivity: Chlorhexidine binds to skin, mucous membranes, and other surfaces, providing a prolonged antimicrobial effect even after rinsing, a key differentiator from many other disinfectants.

- Low Resistance Profile: Due to its multiple modes of action (disrupting cell membranes and precipitating intracellular contents), resistance development is generally slow and less prevalent compared to some antibiotics.

- Versatility: Available in various salt forms and concentrations, allowing for tailored applications from aqueous solutions to alcoholic preparations and powders.

- Cost-Effectiveness: Its high efficacy at low concentrations and persistent action often results in a lower overall cost of use compared to less potent or shorter-acting alternatives.

Vendor Comparison: Key Differentiators

Choosing the right supplier for Chlorhexidine is critical for ensuring product quality, supply chain reliability, and regulatory compliance. Below is a comparison table highlighting key attributes to consider when evaluating vendors.

| Attribute | HBGX Chemical (Our Offering) | Typical Competitor A | Typical Competitor B |

|---|---|---|---|

| Product Purity | ≥ 99.5% (EP/USP/BP Grade) | Typically ≥ 99.0% | Varies, sometimes < 99.0% |

| Regulatory Compliance | ISO 9001, ISO 14001, cGMP compliant, REACH pre-registered. Comprehensive documentation (DMF available). | May have ISO 9001, limited cGMP; often lacks comprehensive regulatory files. | Basic certifications, potentially non-compliant for highly regulated markets. |

| Customization Options | Custom concentrations, salt forms, packaging, purity levels available upon request. | Limited customization, primarily standard offerings. | No customization. |

| Lead Time (Standard Orders) | 2-4 weeks (expedited options available). | 3-6 weeks, less flexible. | Longer, often 6-8 weeks, unstable. |

| Technical Support | Dedicated technical team, formulation assistance, application guidance. | Basic product information support. | Minimal to no technical support. |

Customized Solutions and Collaborative Development

Recognizing the unique requirements of our B2B clients, we offer extensive customized solutions for Chlorhexidine. Our R&D team works closely with clients to develop tailored formulations, specific purities, or packaging formats that align precisely with their application needs. This includes:

- Purity Optimization: For highly sensitive applications (e.g., ophthalmic, implantable devices), we can refine purification processes to achieve ultra-high purity grades.

- Concentration & Salt Form Variations: Producing specific concentrations (e.g., non-standard solutions) or alternative salt forms (e.g., dihydrochloride for specific solubility profiles) to meet unique formulation requirements.

- Specialized Packaging: From bulk tankers to small, precisely weighed sachets, we can accommodate diverse packaging needs, including inert gas blanketing for oxygen-sensitive materials.

- Stability Studies & Documentation: Providing comprehensive stability data and regulatory support for custom products, facilitating client registration processes.

Our decades of experience in chemical manufacturing and dedication to client-centric solutions ensure that even the most niche requirements can be met with scientific rigor and commercial viability.

Application Case Studies

Case Study 1: Biocide in Industrial Water Treatment

A leading petrochemical company faced persistent biofilm formation in its cooling water systems, leading to reduced heat exchange efficiency and increased maintenance costs. Traditional biocides provided only short-term efficacy, requiring frequent dosing. We collaborated with their engineering team to implement a tailored Chlorhexidine digluconate solution (2% w/v), integrated into their biocide rotation program. The substantivity of chlorhexidine allowed for a significantly extended dosing interval (from weekly to bi-monthly), reducing chemical consumption by 30% and maintenance shutdowns by 25% over a 12-month period. This resulted in annual savings exceeding $150,000 and improved operational stability.

Case Study 2: Medical Device Disinfectant Formulation

A global medical device manufacturer required a highly effective, non-corrosive disinfectant for pre-sterilization cleaning of reusable surgical instruments. Their existing solution had efficacy limitations against certain resistant strains. We provided a custom-grade Chlorhexidine diacetate powder, formulated for high solubility and stability in their proprietary cleaning solution. Through rigorous testing, the client confirmed superior kill rates against clinically relevant pathogens, achieving a 6-log reduction within 5 minutes, exceeding their target by 2-log. Our consistent supply chain and comprehensive regulatory documentation were key factors in their successful product launch.

Frequently Asked Questions (FAQ)

Q: What are the primary forms of Chlorhexidine offered?

A: We primarily offer Chlorhexidine Digluconate (20% solution), Chlorhexidine Diacetate (powder), and Chlorhexidine Dihydrochloride (powder), each suited for different applications based on solubility and formulation needs. Other custom salt forms can be synthesized upon request.

Q: Is your Chlorhexidine compliant with pharmacopoeial standards?

A: Yes, our Chlorhexidine products are manufactured to meet or exceed the specifications of major pharmacopoeias, including USP (United States Pharmacopeia), EP (European Pharmacopoeia), and BP (British Pharmacopoeia), ensuring suitability for pharmaceutical and medical applications.

Q: What are the storage recommendations for Chlorhexidine?

A: Chlorhexidine products should be stored in tightly sealed containers, protected from light, at controlled room temperature (typically 15-30°C). Specific storage conditions may vary by salt form and concentration, and detailed instructions are provided on the Certificate of Analysis (CoA) and product labeling.

Logistics, Warranty, and Support

Lead Time and Fulfillment

Our streamlined supply chain and robust production capabilities enable us to offer competitive lead times. Standard orders for stock products typically ship within 2-4 weeks. For custom solutions or large-volume contracts, lead times are mutually agreed upon based on project scope and material availability. We manage global logistics, ensuring timely and secure delivery to your facility.

Warranty Commitments

We stand behind the quality of our Chlorhexidine products. All products are guaranteed to meet the specifications detailed in their respective Certificates of Analysis (CoA) and comply with agreed-upon industry standards for a period of 12-24 months from the date of manufacture, provided they are stored and handled as per our recommendations. Any deviation from these specifications will be addressed promptly, including replacement or credit.

Customer Support Information

Our dedicated customer support team is available to assist with technical inquiries, order tracking, and any post-sales support you may require.

- Technical Support: For formulation guidance, application questions, or detailed product data, please contact our technical specialists at techsupport@hbgxchemical.com.

- Sales & Orders: For pricing, quotes, or to place an order, reach out to sales@hbgxchemical.com.

- General Inquiries: info@hbgxchemical.com

- Phone: +86-XXX-XXXX-XXXX (Office Hours: Mon-Fri, 9:00 AM – 5:00 PM CST)

With over 20 years of experience in the chemical industry, we are committed to building long-term partnerships based on trust, quality, and mutual success.

References

- Grand View Research. (2023). Chlorhexidine Market Size, Share & Trends Analysis Report By Application (Pharmaceutical & Medical, Cosmetics, Others), By Region, And Segment Forecasts, 2023 – 2030.

- United States Pharmacopeia (USP). Monograph: Chlorhexidine Digluconate Solution.

- European Pharmacopoeia (EP). Monograph: Chlorhexidine Digluconate.

- Food and Drug Administration (FDA). Guidance for Industry: Chlorhexidine Gluconate Oral Rinse.

Hebei Guangxing Chemical Co., Ltd. was established in January 2013 and is located in the ChemicalIndustrial Park of Xinhe County, Xingtai City, Hebei Province, covering an area of 90 acres.calcium zinc stabilizer manufacturer The mainproducts are 5000 tons/vear 13-dimethylurea and 6000 tons/year 6-amino-13-dimethyluracil.Hebei Guangxing Chemical Co., Ltd. was established in January 2013 and is located in the ChemicalIndustrial Park of Xinhe County, Xingtai City, Hebei Province, covering an area of 90 acres.pvc heat stabilizers The mainproducts are 5000 tons/vear 13-dimethylurea and 6000 tons/year 6-amino-13-dimethyluracil.uracils|super blog