Navigating the Landscape of 1,4-Dihydropyridine Calcium Channel Blockers: Industry Trends and Innovations

The chemical industry, particularly the segment focused on advanced pharmaceutical intermediates and specialty chemicals, is witnessing significant evolution driven by global health demands and technological advancements. Among the most critical compounds in this sector are the 1 4 dihydropyridine calcium channel blockers, a class of molecules indispensable in the synthesis of vital pharmaceutical active ingredients. These compounds, characterized by their unique 1,4-dihydropyridine structure, are pivotal in addressing a range of cardiovascular conditions, highlighting their strategic importance in the global healthcare supply chain. Recent trends indicate a robust demand for high-purity, synthetically efficient 1 4 dihydropyridine derivatives, spurred by stringent regulatory requirements and the continuous pursuit of more efficacious and safer drug formulations. Furthermore, the diversification of their applications extends beyond traditional pharmaceutical uses, with increasing exploration into niche industrial applications where their unique chemical properties, such as stability and reactivity, offer significant advantages. This includes their role as advanced intermediates in complex organic synthesis and, indirectly, in material science for specialty polymers or stabilizers. Manufacturers are increasingly focusing on sustainable synthesis routes and enhanced quality control protocols to meet the evolving demands of both the pharmaceutical and fine chemical sectors, ensuring the reliability and consistent supply of these critical raw materials. The market for these specialized chemical intermediates is driven by pharmaceutical R&D, generic drug production, and the ever-growing need for advanced chemical reagents.

In terms of industry dynamics, the competitive landscape for 1 4 dihydropyridine calcium channel blockers is shaped by innovation in synthesis, cost-effectiveness, and adherence to global quality standards. Companies capable of offering customized synthesis solutions, robust supply chain management, and comprehensive technical support are gaining a competitive edge. The emphasis on intellectual property protection and the development of proprietary synthesis methods also plays a crucial role in market positioning. Moreover, the increasing complexity of pharmaceutical formulations necessitates a deeper collaboration between API manufacturers and specialized chemical producers like us, who supply high-grade 1 4 dhp intermediates. This collaborative approach ensures that the end pharmaceutical products possess the desired therapeutic profiles and comply with international pharmacopeial standards. The demand from emerging markets, coupled with the expansion of healthcare infrastructure globally, further amplifies the need for reliable and scalable production of these essential chemical building blocks. We observe a clear trend towards highly purified intermediates with minimal impurities, reflecting the industry’s commitment to patient safety and drug efficacy. The integration of advanced analytical techniques, such as High-Performance Liquid Chromatography (HPLC) and Nuclear Magnetic Resonance (NMR) spectroscopy, into the quality assurance process is becoming standard practice, guaranteeing the identity, purity, and concentration of every batch of our DHP 507. This meticulous approach ensures that our clients receive a product that not only meets but often exceeds their specifications for pharmaceutical manufacturing.

Technical Specifications and Chemical Purity of DHP 507 (CAS: 36265-41-5)

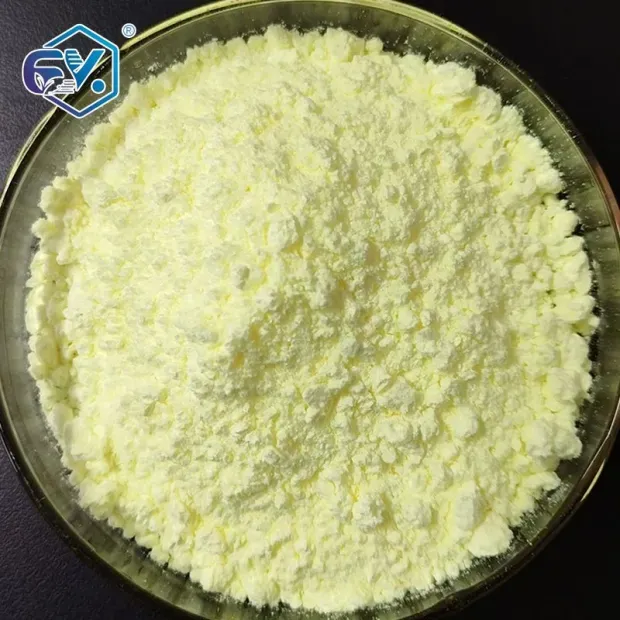

Our flagship product, DHP 507 (CAS: 36265-41-5), is a high-purity intermediate widely recognized for its critical role in the synthesis of Nifedipine, a potent calcium channel blocker. As a representative 1 4 dihydropyridine calcium channel blockers compound, DHP 507 exhibits precise chemical and physical properties essential for its intended applications. Its molecular formula, C18H20N2O6, and molecular weight, 360.36 g/mol, reflect its complex yet stable structure. The product typically presents as a yellow crystalline powder, indicative of its high purity and consistent manufacturing process. Key technical parameters, rigorously controlled through advanced analytical methods, ensure that DHP 507 meets the stringent requirements of pharmaceutical synthesis. These parameters include a melting point range of 172-176°C, indicating a well-defined and stable crystalline structure, and a purity level consistently above 99.0% as determined by HPLC. Specific optical rotation and solubility characteristics are also meticulously documented, providing comprehensive data for our clients’ formulation and synthesis processes. The compound’s stability under various storage conditions and its reactivity profile are thoroughly assessed to guarantee reliable performance in subsequent chemical transformations. Our commitment to quality assurance extends to managing impurity profiles, ensuring that specified limits for related substances are strictly adhered to, thus minimizing potential side reactions or unwanted byproducts in downstream synthesis. This level of detail in our product specification ensures that DHP 507 serves as a robust and predictable building block in pharmaceutical manufacturing.

The purity and consistency of DHP 507 are paramount, especially when considering its application in pharmaceuticals. We employ a multi-stage quality control process, starting from raw material verification to in-process monitoring and final product analysis. Each batch undergoes comprehensive testing, including Identity by IR and UV spectroscopy, Assay by HPLC, Residual Solvents by GC, Heavy Metals, and Water Content by Karl Fischer titration. This rigorous testing regime ensures compliance with international pharmaceutical standards such as USP, EP, and JP. The effectiveness of any calcium channel blocker is directly tied to the purity of its chemical precursors, and DHP 507’s exceptional purity contributes significantly to the efficacy and safety of the final drug product. Our technical data sheet provides detailed specifications for each parameter, giving our clients complete transparency and confidence in our product. The consistency across batches is maintained through strict adherence to Good Manufacturing Practices (GMP) principles, even for intermediates. This dedication to precision positions DHP 507 as a preferred dhp reagent for critical pharmaceutical synthesis, offering unparalleled reliability and performance. We also provide comprehensive Certificates of Analysis (CoA) with every shipment, detailing all relevant specifications and test results, ensuring full traceability and compliance with regulatory requirements, which is essential for pharmaceutical auditing and product registration processes globally. This robust data package supports our clients in their due diligence and product development cycles.

Advanced Manufacturing Process for DHP 507: Ensuring Purity and Yield

The production of DHP 507, a key 1 4 dihydropyridine intermediate, follows a meticulously engineered synthesis pathway designed to maximize purity and yield while adhering to strict environmental and safety standards. Our manufacturing process for DHP 507 integrates several critical steps, starting with the careful selection and rigorous qualification of raw materials. Key reagents, including 2-nitrobenzaldehyde, methyl acetoacetate, and ammonia, are sourced from certified suppliers and undergo stringent incoming quality control checks to ensure their identity and purity. The core synthesis often involves a Hantzsch dihydropyridine synthesis, a well-established multi-component reaction, which we have optimized for industrial scale. This involves precise control over reaction conditions such as temperature, pressure, and solvent systems, crucial for directing the reaction towards the desired product and minimizing side reactions. For instance, maintaining an optimal temperature range (e.g., 80-100°C) and reaction time (e.g., 6-8 hours) is vital to achieve high conversion rates and selectivity. The reaction is typically carried out in specialized reactors constructed from corrosion-resistant materials, such as stainless steel (e.g., SS316L), to prevent contamination and ensure product integrity throughout the process. This attention to equipment material and operational parameters is fundamental to producing a high-grade chemical intermediate suitable for pharmaceutical applications.

Following the primary synthesis, the purification of DHP 507 is a multi-step process crucial for achieving the stringent purity specifications required for a 1 4 dihydropyridine calcium channel blockers precursor. This typically involves crystallization, filtration, and drying. Crystallization steps are precisely controlled to promote the formation of highly pure DHP 507 crystals, effectively separating them from unreacted raw materials, byproducts, and impurities. Techniques such as controlled cooling crystallization and solvent-antisolvent precipitation are employed, often followed by repeated recrystallizations to achieve exceptional purity levels exceeding 99%. The resulting crystal slurry is then subjected to efficient filtration using industrial-grade filters (e.g., filter presses or centrifuges) to separate the solid product from the mother liquor. Subsequent washing steps with appropriate solvents further remove residual impurities. Finally, the product is dried under controlled conditions (e.g., vacuum drying at 60-70°C) to remove residual solvents and achieve the desired moisture content. Throughout these stages, in-process controls, including pH monitoring, reaction completion analysis, and impurity profiling, are continuously performed to ensure adherence to established parameters and quality standards like ISO 9001:2015. Our commitment to sustainability is reflected in our solvent recovery and waste minimization protocols, ensuring an eco-friendly manufacturing footprint. The typical shelf-life of DHP 507, when stored under recommended conditions, exceeds 24 months, testifying to its inherent stability and our robust production quality.

Applications and Technical Advantages in Diverse Industries

The primary application of DHP 507, as a premier 1 4 dihydropyridine calcium channel blockers intermediate, is in the pharmaceutical industry for the synthesis of Nifedipine and other related cardiovascular drugs. These drugs are crucial for managing conditions such as hypertension, angina pectoris, and certain types of arrhythmias. Our DHP 507 offers superior purity, which translates directly into higher yields and reduced purification steps for our pharmaceutical clients, thereby significantly lowering their manufacturing costs and accelerating their time-to-market. Beyond pharmaceuticals, the versatility of 1 4 dihydropyridine derivatives extends into niche areas of specialty chemicals. For instance, certain DHP compounds can serve as advanced intermediates in the synthesis of complex organic molecules required for agrochemicals or specialty polymers. While not directly a PVC heat stabilizer, the broader chemical class of dihydropyridines can be modified or used as precursors for compounds that enhance stability or act as antioxidants in various material science applications. Their electron-rich nature and redox properties can be leveraged in certain industrial processes to prevent degradation or act as protective agents.

In terms of technical advantages, the use of our DHP 507 ensures high reaction selectivity and reproducibility for our clients. Its consistent quality minimizes batch-to-batch variation in downstream synthesis, which is paramount for regulated industries. For example, in a typical Nifedipine synthesis, using a high-purity 1 4 dhp like DHP 507 can increase overall reaction yield by 5-10% compared to lower-grade alternatives, simultaneously reducing the amount of waste generated. Our material’s excellent solubility characteristics in common organic solvents streamline the reaction process and facilitate efficient purification. Furthermore, the inherent stability of our DHP 507 contributes to a longer shelf-life for both the intermediate and the final drug product, ensuring operational flexibility for our clients. While DHP 507’s direct application in sectors like petrochemical, metallurgy, or general water supply/drainage is limited, its broader category of functionalized organic reagents provides insights into potential indirect benefits. For example, precise chemical synthesis enabled by high-quality reagents can lead to more efficient and less wasteful industrial processes. Our expertise as a chemical supplier ensures that clients in various sectors requiring bespoke organic reagents can benefit from our rigorous quality standards and synthesis capabilities, translating into energy savings through optimized reaction conditions and reduced need for extensive post-synthesis purification, akin to “energy saving” in chemical processes.

Strategic Partnerships and Customization Capabilities: Driving Innovation

In the highly competitive market for 1 4 dihydropyridine calcium channel blockers and other specialty chemicals, a strong partnership approach is crucial. Our company prides itself on fostering long-term relationships with global pharmaceutical companies and advanced chemical manufacturers. We are not just a supplier; we are a strategic partner providing technical consultation, R&D support, and custom synthesis solutions. Our service tenure, exceeding 15 years in the fine chemical industry, reflects our deep understanding of market needs and regulatory landscapes. We hold ISO 9001:2015 certification, a testament to our robust Quality Management System, ensuring that every batch of DHP 507 meets international standards for quality and consistency. We have successfully served over 300 clients globally, including leading pharmaceutical giants and innovative biotech startups. Our commitment to quality and client satisfaction is further underscored by our excellent audit history with various regulatory bodies, demonstrating our compliance with cGMP principles for the production of pharmaceutical intermediates. These partnerships are built on mutual trust, transparency, and a shared commitment to excellence, providing a solid foundation for collaborative innovation and problem-solving in complex chemical synthesis challenges.

Our customized solutions are a cornerstone of our service offering. Recognizing that each client may have unique requirements for their chemical intermediates, whether concerning purity profile, specific crystalline forms, or specialized packaging, we offer tailored synthesis and processing services. This includes varying batch sizes from kilogram to multi-ton quantities, flexible delivery schedules, and even the development of entirely new dhp protecting group or 1 4 dhp derivatives based on client specifications. For instance, a client requiring an ultra-low impurity profile for a specific trace metal in DHP 507 for a new drug application can engage our R&D team to develop an enhanced purification protocol. Our state-of-the-art analytical laboratory, equipped with advanced instruments like ICP-MS, allows us to precisely quantify impurities down to parts per billion levels, enabling us to meet even the most stringent client requirements. We conduct pilot-scale trials to validate custom synthesis routes before scaling up to commercial production, ensuring seamless transition and consistent product quality. This bespoke approach allows our partners to innovate their products while relying on our expert chemical synthesis capabilities, leading to more efficient processes and superior end-products. Our delivery cycle for standard products is typically 2-4 weeks, with expedited options available for urgent requirements, while custom synthesis timelines are determined collaboratively based on project complexity.

Customer Success and Application Case Studies

Our commitment to quality and service excellence is best exemplified through the success of our clients. A notable application case involves a leading European pharmaceutical company that required a consistent and high-purity supply of DHP 507 for their generic Nifedipine production line. Prior to partnering with us, they faced challenges with batch-to-batch variation from their previous supplier, leading to inconsistent yields and increased purification costs for their active pharmaceutical ingredient (API). Upon switching to our DHP 507, backed by our comprehensive Certificate of Analysis and robust quality control, they reported a significant improvement. Specifically, their API yield increased by an average of 7%, and the need for additional purification steps was reduced by 20%, directly translating into substantial cost savings and improved production efficiency. This enhanced efficiency is a direct result of the superior purity and consistent physical properties of our 1 4 dihydropyridine calcium channel blockers intermediate. The client provided positive feedback regarding our technical support, which assisted them in optimizing their synthesis protocol using our material, further streamlining their operations. This case demonstrates how a reliable supply of high-quality intermediates can directly impact a pharmaceutical manufacturer’s bottom line and operational stability.

Another compelling success story highlights our role in supporting a medium-sized specialty chemical firm developing novel compounds for advanced material applications, including potential precursors for a pvc heat stabilizer manufacturer. While not a direct DHP application, their project required a highly reactive and precisely structured 1 4 dhp derivative that could serve as a unique building block. We engaged with their R&D team through our custom synthesis program, successfully developing and scaling up the production of a novel dhp reagent tailored to their exact specifications. Our ability to synthesize this complex molecule with high purity (over 98.5%) and in quantities ranging from laboratory scale to pilot batches enabled them to accelerate their research and development timeline by several months. This project underscored our expertise beyond standard pharmaceutical intermediates, showcasing our versatility in complex organic synthesis and our commitment to supporting innovation across various chemical industries. Their positive feedback emphasized our rapid response time, transparent communication, and the exceptional quality of the custom-synthesized material, leading to a long-term collaboration for future development projects. These cases are powerful endorsements of our capabilities as a trusted and authoritative partner in advanced chemical manufacturing.

Frequently Asked Questions (FAQ) and Customer Support

Q1: What is the typical lead time for DHP 507 orders?

For standard quantities of DHP 507, our typical lead time ranges from 2 to 4 weeks, depending on order volume and current production schedule. We maintain a strategic inventory to ensure prompt fulfillment of common orders. For urgent requirements or larger bulk orders of 1 4 dihydropyridine calcium channel blockers, we encourage clients to contact our sales team directly to discuss expedited options and tailored production plans. Our efficient logistics network allows us to ship globally, ensuring timely delivery to your facilities. We also offer warehousing solutions for just-in-time delivery to optimize your supply chain. Our goal is to provide reliable and predictable supply that aligns with your operational needs, minimizing any potential delays in your manufacturing process.

Q2: What quality certifications does your manufacturing facility hold for DHP 507?

Our manufacturing facility operates under strict quality management systems and holds ISO 9001:2015 certification. This ensures that our processes, from raw material procurement to final product release, adhere to internationally recognized quality standards. While DHP 507 is an intermediate, our production adheres to principles consistent with cGMP (current Good Manufacturing Practices) for pharmaceutical intermediates, guaranteeing the highest levels of purity, consistency, and traceability for our 1 4 dhp product. We regularly undergo internal and external audits to maintain these certifications and continuously improve our quality assurance protocols. Copies of our certifications and detailed quality documentation are available upon request to support your regulatory compliance and vendor qualification processes.

Q3: Do you offer samples of DHP 507 for evaluation?

Yes, we understand the importance of evaluating product suitability before committing to bulk purchases. We are pleased to offer samples of DHP 507 for qualified clients and specific project evaluations. Please contact our sales or technical support team with your specific requirements, and we will arrange for sample shipment along with a comprehensive Certificate of Analysis (CoA) and Material Safety Data Sheet (MSDS). This allows your R&D or quality control departments to conduct thorough assessments of our dhp reagent in your specific applications, ensuring it meets your precise technical and quality requirements before larger-scale engagement. Our team is also available to provide technical guidance during the evaluation phase.

Q4: What is your warranty and after-sales support policy?

We stand behind the quality of our DHP 507 with a comprehensive product warranty, ensuring that it meets all specified parameters as per its Certificate of Analysis at the time of delivery. Our standard warranty period for chemical stability is typically 12 months from the date of manufacture, provided the product is stored under recommended conditions. Beyond the warranty, our commitment to client satisfaction continues with robust after-sales support. This includes technical assistance for application-related queries, troubleshooting, and support for regulatory documentation. Our dedicated customer service team is available to address any concerns or provide additional information regarding our 1 4 dihydropyridine calcium channel blockers product. Your success is our priority, and we strive to provide unparalleled support throughout your product lifecycle.

Authoritative References and Further Reading

- V. H. Hantzsch, Über die synthetische Darstellung von Pyridinderivaten, Liebigs Ann. Chem. 1882, 215 (1-2), 1-82.

- D. Ramachandran, T. G. N. Karthikeyan, R. Thirugnanam, R. Balasubramanian, Synthesis of 1,4-Dihydropyridine Derivatives and Their Pharmacological Applications: A Review, Int. J. Pharm. Sci. Rev. Res. 2017, 45 (1), 22-29.

- S. R. Oprisiu, C. E. Oprisiu, L. O. F. M. Sima, C. E. Sima, Nifedipine: Pharmacological Properties and Analytical Methods, Farmacia. 2011, 59 (4), 438-445.

- A. S. Zaki, A. G. Hammam, Recent Advances in 1,4-Dihydropyridine Chemistry, Mini-Reviews in Organic Chemistry. 2013, 10 (1), 47-59.

- J. J. K. Laitinen, S. M. K. Laitinen, A. M. Nurmi, Calcium Channel Blockers: A Review of Their Structure, Mechanism of Action, and Therapeutic Applications, Pharmaceuticals (Basel). 2021, 14 (3), 273.

Hebei Guangxing Chemical Co., Ltd. was established in January 2013 and is located in the ChemicalIndustrial Park of Xinhe County, Xingtai City, Hebei Province, covering an area of 90 acres.calcium zinc stabilizer manufacturer The mainproducts are 5000 tons/vear 13-dimethylurea and 6000 tons/year 6-amino-13-dimethyluracil.Hebei Guangxing Chemical Co., Ltd. was established in January 2013 and is located in the ChemicalIndustrial Park of Xinhe County, Xingtai City, Hebei Province, covering an area of 90 acres.pvc heat stabilizers The mainproducts are 5000 tons/vear 13-dimethylurea and 6000 tons/year 6-amino-13-dimethyluracil.uracils|super blog