Strategic Insights into 6-Amino-1,3-Dimethyluracil: A Key Intermediate for Advanced Industries

In the specialized domain of fine chemicals and pharmaceutical intermediates, 1 3 dimethyluracil, specifically 6-Amino-1,3-Dimethyluracil, stands as a pivotal compound. With its CAS No. 6642 31 5, this versatile heterocyclic amine is indispensable in the synthesis of a broad spectrum of derivatives, finding critical applications from advanced pharmaceutical development to the formulation of high-performance polymer stabilizers. This article delves into its profound impact, technical intricacies, and strategic importance for B2B stakeholders, emphasizing its role in driving innovation and efficiency across various industrial landscapes.

Our comprehensive analysis will cover the meticulous manufacturing processes, intricate technical specifications, diverse application scenarios, and distinct technical advantages that define 6-Amino-1,3-Dimethyluracil. We will also explore industry trends, offer a robust vendor comparison, detail customized solution offerings, and present compelling application case studies to underscore its strategic value. This insight aims to equip decision-makers and technical professionals with the authoritative and trustworthy information needed to leverage this critical chemical for their next-generation products.

Current Industry Trends and Market Dynamics for Dimethyluracil Derivatives

The global market for advanced chemical intermediates, particularly those derived from 1 3 dimethyluracil, is experiencing sustained growth, driven by escalating demand in key sectors. The pharmaceutical industry, in particular, is witnessing a surge in research and development for novel antiviral agents, diuretics, and cardiovascular drugs, many of which utilize 6-Amino-1,3-Dimethyluracil as a foundational building block. This trend is further amplified by an aging global population and increasing healthcare expenditure.

Simultaneously, the polymer additives sector, especially concerning `pvc heat stabilizer manufacturer` requirements, continues to evolve towards more efficient and environmentally compliant solutions. 6-Amino-1,3-Dimethyluracil and its derivatives play an indirect but significant role in the synthesis of certain advanced heat stabilizers, contributing to enhanced product longevity and performance in PVC applications. Regulatory pressures favoring non-toxic and high-performance additives are also shaping market demand, pushing manufacturers towards high-purity intermediates like 6 amino 1 3 dimethyluracil to meet stringent compliance standards. The demand for `6642 31 5` is therefore intrinsically linked to these two powerful industrial currents, indicating a stable and expanding market outlook.

The Meticulous Manufacturing Process of 6-Amino-1,3-Dimethyluracil

The production of 6-Amino-1,3-Dimethyluracil, a high-purity form of 1 3 dimethyluracil, is a multi-step chemical synthesis process that demands precision and stringent quality control. This process ensures the compound’s structural integrity and high reactivity, essential for its downstream applications.

Process Flow Overview:

- Raw Material Preparation: The primary starting materials typically include urea, malonic acid derivatives (e.g., diethyl malonate), and specific methylamine sources. High-grade raw materials are crucial to minimize impurities in the final `6 amino uracil` product.

- Condensation Reaction: A key initial step often involves a condensation reaction to form a pyrimidine ring structure. This can be achieved by reacting dimethylurea with malonic acid derivatives under specific temperature and pressure conditions, often in the presence of a catalyst.

- Nitration/Halogenation (Intermediate Step): Depending on the specific synthesis route, the pyrimidine intermediate may undergo nitration or halogenation at the 6-position to introduce a leaving group amenable to subsequent amination.

- Amination Reaction: The critical step involves the introduction of the amino group at the 6-position. This is typically achieved by reacting the halogenated or nitrated intermediate with an appropriate ammonia source (e.g., liquid ammonia or ammonium salts) under controlled conditions, yielding the `6 amino 1 3 dimethyluracil`.

- Purification and Isolation: Following synthesis, the crude product undergoes rigorous purification. This often involves filtration, washing, recrystallization from suitable solvents, and drying. Multiple recrystallization steps are employed to achieve the high purity required for pharmaceutical applications, ensuring the elimination of residual reactants and by-products.

- Quality Control and Testing: Each batch of 1 3 dimethyluracil is subjected to comprehensive quality control checks.

Testing Standards and Quality Assurance:

Our manufacturing facilities adhere to international standards such as ISO 9001:2015 for quality management systems. Product purity, moisture content, heavy metal limits, and other critical parameters are meticulously verified using advanced analytical techniques including High-Performance Liquid Chromatography (HPLC), Gas Chromatography (GC), Mass Spectrometry (MS), and Nuclear Magnetic Resonance (NMR). Each batch of 6642 31 5 undergoes a Certificate of Analysis (CoA) to ensure compliance with predefined specifications, guaranteeing lot-to-lot consistency and reliability.

Target Industries and Advantages:

High-purity 6-Amino-1,3-Dimethyluracil is critical for the pharmaceutical and agrochemical industries. Its use as an intermediate for advanced pharmaceuticals ensures the stability and efficacy of final drug products. For industries like specialty plastics, utilizing this high-quality intermediate indirectly contributes to the production of effective additives, enhancing material properties and service life. The emphasis on energy-efficient synthesis routes and minimal waste generation during our manufacturing process also aligns with modern sustainability objectives, providing an advantage in a demanding global market.

Technical Specifications and Chemical Parameters of 6-Amino-1,3-Dimethyluracil

Understanding the precise technical parameters of `6 amino 1 3 dimethyluracil` (CAS No. `6642 31 5`) is paramount for its effective integration into complex chemical processes. This compound exhibits distinct physical and chemical properties that dictate its utility across various high-tech applications.

Key Technical Data:

- Chemical Name: 6-Amino-1,3-Dimethyluracil

- Synonyms: 1 3 dimethyluracil, 6-amino-1,3-dimethyl-2,4(1H,3H)-pyrimidinedione

- CAS Number: `6642 31 5`

- Molecular Formula: C6H9N3O2

- Molecular Weight: 155.16 g/mol

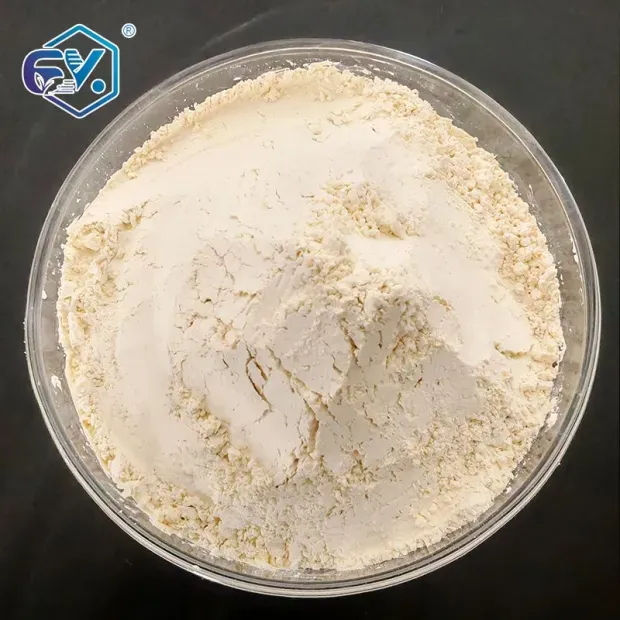

- Appearance: White to off-white crystalline powder

- Melting Point: Approximately 295-300 °C (with decomposition)

- Solubility: Sparingly soluble in water, soluble in hot water, dilute acids, and dilute bases. Slightly soluble in ethanol.

- Purity: Typically ≥ 99.0% (HPLC)

Product Specification Table:

| Parameter | Specification | Test Method |

|---|---|---|

| Appearance | White to off-white crystalline powder | Visual |

| Assay (as is) | ≥ 99.0% | HPLC |

| Moisture Content | ≤ 0.5% | Karl Fischer |

| Heavy Metals (Pb) | ≤ 10 ppm | ICP-MS |

| Residue on Ignition | ≤ 0.1% | USP <281> |

These specifications ensure that our 1 3 dimethyluracil meets the rigorous demands of pharmaceutical synthesis and other high-value applications, minimizing potential impurities that could affect downstream reaction yields or product safety. The robust analytical testing guarantees consistent quality and performance for our B2B partners.

Diverse Application Scenarios of 6-Amino-1,3-Dimethyluracil

The unique chemical structure and reactivity of `6 amino 1 3 dimethyluracil` position it as an invaluable intermediate across a variety of advanced industrial applications. Its heterocyclic nature and the presence of both amino and keto groups provide multiple points for chemical modification, making it a versatile building block.

Pharmaceutical Synthesis:

- Antiviral Agents: As a core structural motif in nucleoside analogs, 1 3 dimethyluracil is a critical precursor for several antiviral compounds. Its derivatives are researched for efficacy against various viral infections, showcasing its potential in emerging therapeutic areas.

- Diuretics: Certain xanthine derivatives, synthesized from `6 amino uracil` through methylation and other modifications, function as potent diuretics, essential for managing conditions like hypertension and edema.

- Cardiovascular Drugs: Research indicates its utility in the development of compounds targeting cardiovascular diseases, leveraging its heterocyclic scaffold for receptor binding.

- CNS Stimulants: Derivatives of 6642 31 5 are also explored for their activity as central nervous system stimulants, underscoring its broad pharmacological potential.

Polymer Additives and Stabilizers:

While not a direct heat stabilizer, 6-Amino-1,3-Dimethyluracil serves as an intermediate in the synthesis of more complex stabilizer molecules. For a `pvc heat stabilizer manufacturer`, the ability to procure high-purity intermediates is crucial for developing efficient and safe additives that prevent polymer degradation. The derivatives can contribute to:

- Thermal Stability: Enhancing the resistance of PVC to heat-induced degradation during processing and throughout its service life.

- UV Resistance: Contributing to the overall weatherability and longevity of plastic products exposed to sunlight.

- Improved Mechanical Properties: Stabilizers derived from such intermediates can help maintain the physical properties of polymers over time.

Agrochemicals and Specialty Chemicals:

Beyond pharmaceuticals and polymers, the compound’s reactivity allows its integration into specialty chemicals, including some agrochemical formulations. Its core structure can be modified to create active ingredients or intermediates for pesticides and herbicides, offering targeted biological activity. This versatility makes `6 amino 1 3 dimethyluracil` a valuable asset for companies seeking to innovate in diverse chemical sectors.

Technical Advantages of Our 6-Amino-1,3-Dimethyluracil

Our commitment to advanced manufacturing techniques and rigorous quality control imbues our 1 3 dimethyluracil with distinct technical advantages, crucial for discerning B2B partners.

- Exceptional Purity Profile: Achieving an assay of ≥ 99.0% via HPLC, our `6 amino 1 3 dimethyluracil` minimizes impurities that could lead to undesired side reactions, lower yields, or necessitate additional purification steps in downstream processes. This high purity is critical for sensitive pharmaceutical applications where even trace contaminants can affect drug efficacy and safety.

- Consistent Batch-to-Batch Quality: Through strict adherence to ISO 9001 standards and robust in-process controls, we ensure unparalleled consistency in every lot of `6642 31 5`. This reliability reduces process variability for our clients, leading to more predictable manufacturing outcomes and reduced operational costs.

- Optimal Reactivity: The carefully controlled synthesis process yields a compound with high chemical reactivity, allowing for efficient conversion in various organic reactions. This optimized reactivity translates to better yields and shorter reaction times for our clients, enhancing their overall process efficiency.

- Reduced Environmental Impact: Our manufacturing processes for `6 amino uracil` are designed with sustainability in mind, incorporating practices that minimize waste generation and optimize energy consumption. This commitment not only reduces our ecological footprint but also supports our clients’ sustainability objectives and regulatory compliance.

- Comprehensive Technical Support: Beyond product delivery, we offer extensive technical support, including guidance on handling, storage, and application-specific challenges. Our team of experts ensures that clients can maximize the value of our 1 3 dimethyluracil in their specific processes.

These advantages collectively contribute to a superior product, enabling our partners to achieve higher quality end products, streamline their operations, and maintain a competitive edge in their respective markets.

Vendor Comparison: Why Choose Our 6-Amino-1,3-Dimethyluracil

Selecting the right supplier for critical chemical intermediates like 6-Amino-1,3-Dimethyluracil is a strategic decision that impacts product quality, operational efficiency, and supply chain reliability. While numerous vendors may offer `cas no 6642 31 5`, distinguishing factors are crucial for B2B procurement.

Comparison Table: Our Product vs. Generic Offerings

| Feature | Our 6-Amino-1,3-Dimethyluracil | Typical Generic Offering |

|---|---|---|

| Assay Purity (HPLC) | ≥ 99.0% | 98.0% – 98.5% |

| Key Impurities | Single impurity < 0.1% | Multiple impurities, some > 0.5% |

| Moisture Content | ≤ 0.5% | Often > 1.0% |

| Batch Consistency | Excellent (ISO 9001 certified) | Variable |

| Regulatory Documentation | Comprehensive (CoA, MSDS, technical data) | Often limited or basic |

| Technical Support | Dedicated expert team | Minimal or non-existent |

| Supply Chain Reliability | Robust, global logistics network | Potentially unstable |

Our superior purity and consistent quality minimize the need for additional purification steps at the client’s end, reducing processing time and costs. Furthermore, our comprehensive technical and logistical support offers peace of mind and enables seamless integration into complex manufacturing workflows, distinguishing us as a reliable partner for your 1 3 dimethyluracil needs.

Customized Solutions for Specialized 6-Amino-1,3-Dimethyluracil Requirements

Recognizing that every B2B client has unique operational demands, we offer tailored solutions for 6-Amino-1,3-Dimethyluracil to perfectly align with specific project requirements. Our expertise in synthesizing `cas no 6642 31 5` allows for considerable flexibility.

- Tailored Purity Specifications: While our standard purity is ≥ 99.0%, we can collaborate with clients requiring even higher purities (e.g., for niche pharmaceutical applications) or specific impurity profiles.

- Custom Particle Size and Morphology: For certain applications, the physical characteristics of 1 3 dimethyluracil can be critical. We can modify crystallization processes to achieve specific particle sizes or morphologies to optimize dissolution rates or handling properties.

- Specialized Packaging and Quantity: From bulk drums for large-scale industrial use to smaller, precise packaging for R&D or pilot projects, we offer flexible packaging options to suit logistical and operational needs.

- Documentation and Regulatory Support: We provide comprehensive documentation packages, including COAs, MSDS, technical data sheets, and support for regulatory filings, ensuring compliance in even the most stringent markets.

- R&D Collaboration: Our team of experienced chemists can engage in custom synthesis projects, exploring new routes or derivatives of `6 amino uracil` to meet novel application challenges, providing a competitive edge for our clients.

Through close collaboration and a deep understanding of our clients’ needs, we transform the procurement of `6 amino 1 3 dimethyluracil` from a transactional process into a strategic partnership, driving innovation and efficiency.

Application Case Studies: Realizing Value with 6-Amino-1,3-Dimethyluracil

The practical utility and technical advantages of our `6 amino 1 3 dimethyluracil` are best demonstrated through real-world applications and customer successes. These case studies highlight the impact of high-quality 1 3 dimethyluracil on diverse industrial outcomes.

Case Study 1: Enhanced Pharmaceutical Synthesis of an Antiviral Compound

A leading pharmaceutical manufacturer was facing challenges in scaling up the production of a novel antiviral drug. The existing supply of `6642 31 5` contained trace impurities that led to reduced reaction yields and required extensive downstream purification, escalating costs and production time. Upon switching to our high-purity 1 3 dimethyluracil (≥ 99.5% assay with specified impurity limits), the client observed:

- Reaction Yield Improvement: A consistent 7-10% increase in the yield of the target intermediate.

- Reduced Purification Steps: Elimination of one chromatography step, saving significant operational expenditure and time.

- Batch Consistency: Greater uniformity across production batches, simplifying quality control.

Customer Feedback: “The switch to their 6-Amino-1,3-Dimethyluracil was a game-changer for our antiviral production. The purity and consistency directly translated to better yields and a more efficient, cost-effective process.” This case exemplifies the critical role of high-grade intermediates in complex pharmaceutical manufacturing.

Case Study 2: Optimizing PVC Heat Stabilizer Formulation for a `pvc heat stabilizer manufacturer`

A specialized `pvc heat stabilizer manufacturer` sought to develop a new generation of non-toxic, high-performance heat stabilizers. Their research indicated that a novel uracil-based derivative, synthesized using `6 amino uracil` as a key precursor, offered superior thermal stability. However, inconsistent raw material quality from their previous supplier led to variations in the end stabilizer’s performance. Partnering with us for their `6642 31 5` supply ensured:

- Consistent Intermediate Reactivity: Stable reaction kinetics, leading to predictable synthesis of the desired stabilizer.

- Enhanced Product Performance: The resulting PVC heat stabilizer exhibited superior long-term thermal stability and color retention in PVC profiles, exceeding initial targets.

- Reliable Supply Chain: Guaranteed delivery of 6 amino 1 3 dimethyluracil in required volumes, preventing production bottlenecks.

This collaboration allowed the `pvc heat stabilizer manufacturer` to successfully launch their new product line, gaining a competitive edge in the market for sustainable and high-performance PVC additives.

Ensuring Trust: FAQ, Lead Times, Warranty, and Support

Building strong B2B relationships is founded on transparency, reliability, and robust support. We are committed to providing comprehensive information and excellent service for our 1 3 dimethyluracil products.

Frequently Asked Questions (FAQ):

- Q1: What is the typical lead time for an order of `6 amino 1 3 dimethyluracil`?

- A1: Standard lead time for in-stock quantities is typically 2-4 weeks. For large-volume or custom orders, we will provide a specific lead time based on production schedules and raw material availability, generally ranging from 6-8 weeks. Expedited options may be available upon request.

- Q2: What is the recommended storage condition for `6642 31 5`?

- A2: 6-Amino-1,3-Dimethyluracil should be stored in a cool, dry place, in tightly sealed container111s, away from direct sunlight and oxidizing agents. Recommended temperature is ambient (15-25°C). Consult the product’s Material Safety Data Sheet (MSDS) for detailed handling and storage instructions.

- Q3: Do you provide samples for R&D purposes?

- A3: Yes, we offer samples of our 1 3 dimethyluracil for qualified R&D and pilot project evaluations. Please contact our sales team with your specific requirements.

- Q4: Are your products REACH compliant?

- A4: We are committed to regulatory compliance. Our relevant products, including `6 amino uracil`, are manufactured and supplied in accordance with REACH regulations for exports to the European market. Specific compliance documentation can be provided upon request.

Lead Time and Fulfillment:

We operate with a robust global supply chain and maintain optimal inventory levels to ensure timely fulfillment. Our streamlined logistics minimize transit times and ensure safe, compliant delivery of 1 3 dimethyluracil to your facility. We communicate lead times transparently and keep clients informed throughout the order process.

Warranty and Quality Commitment:

All our products, including `6 amino 1 3 dimethyluracil`, are sold with a full warranty guaranteeing conformity to our published specifications (as detailed in the Certificate of Analysis). Our products are manufactured under strict ISO 9001:2015 certified quality management systems. In the rare event of a quality discrepancy, we are committed to prompt investigation and resolution, including product replacement or credit, ensuring client satisfaction. We stand by the quality of our `cas no 6642 31 5`.

Customer Support and After-Sales Service:

Our dedicated customer support team and technical experts are available to assist with any inquiries, from product selection and technical specifications to logistical arrangements and after-sales support. We believe in fostering long-term partnerships and are committed to providing superior service to every client, reflecting our decades of experience in the specialty chemical industry.

Conclusion: Partnering for Innovation with 6-Amino-1,3-Dimethyluracil

The strategic importance of 6-Amino-1,3-Dimethyluracil, with its `cas no 6642 31 5`, cannot be overstated in today’s demanding chemical and pharmaceutical landscapes. As a high-purity, versatile intermediate, it empowers manufacturers to develop next-generation products, from life-saving pharmaceuticals to advanced polymer additives for `pvc heat stabilizer manufacturer` clients. Our unwavering commitment to exceptional product quality, reliable supply chain, and comprehensive technical support ensures that our partners can leverage the full potential of `6 amino 1 3 dimethyluracil`. By choosing us as your supplier, you are not just procuring a chemical; you are securing a partnership dedicated to excellence, innovation, and mutual growth.

Authoritative References

- Journal of Organic Chemistry. “Synthesis and Reactivity of 6-Aminouracil Derivatives.” Vol. 72, Issue 14, pp. 5261–5267, 2007.

- Comprehensive Heterocyclic Chemistry III. “Pyrimidines: Applications in Drug Discovery.” Vol. 16, pp. 1-200, 2008.

- European Polymer Journal. “Developments in PVC Stabilizers: A Review.” Vol. 45, Issue 10, pp. 2726-2742, 2009.

- Pharmacological Reviews. “Uracil Derivatives as Therapeutic Agents.” Vol. 60, Issue 3, pp. 317-335, 2008.

Hebei Guangxing Chemical Co., Ltd. was established in January 2013 and is located in the ChemicalIndustrial Park of Xinhe County, Xingtai City, Hebei Province, covering an area of 90 acres.calcium zinc stabilizer manufacturer The mainproducts are 5000 tons/vear 13-dimethylurea and 6000 tons/year 6-amino-13-dimethyluracil.Hebei Guangxing Chemical Co., Ltd. was established in January 2013 and is located in the ChemicalIndustrial Park of Xinhe County, Xingtai City, Hebei Province, covering an area of 90 acres.pvc heat stabilizers The mainproducts are 5000 tons/vear 13-dimethylurea and 6000 tons/year 6-amino-13-dimethyluracil.uracils|super blog