Introduction to Advanced Antimicrobial Solutions

In an era where antimicrobial resistance poses a significant global health challenge, the demand for highly effective, safe, and reliable antiseptic agents is paramount across various industries. Among these, Chlorhexidine stands out as a critical compound, widely recognized for its broad-spectrum efficacy and persistent antimicrobial activity. This comprehensive overview delves into the technical aspects, application versatility, and strategic advantages of this essential chemical, offering B2B decision-makers and technical professionals the insights needed for informed procurement and application.

Industry Trends in Antimicrobial Technology and Hygiene Standards

The global market for antimicrobials is experiencing robust growth, driven by escalating concerns over hospital-acquired infections (HAIs), heightened regulatory scrutiny in healthcare and food industries, and consumer demand for enhanced hygiene in personal care products. Data from Grand View Research indicates the global antiseptic and disinfectant market size was valued at USD 24.3 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 11.2% from 2023 to 2030. This growth is significantly influenced by the need for effective, long-lasting agents. Innovations focus on developing less irritating, more potent, and environmentally conscious formulations. As industries strive for superior infection control and product preservation, compounds like Chlorhexidine, with its proven efficacy and favorable safety profile, remain central to these advancements, ensuring compliance with stringent international standards such as ISO 13485 for medical devices and FDA guidelines for pharmaceutical ingredients.

The Advanced Manufacturing Process of Chlorhexidine

The production of high-purity Chlorhexidine involves a series of meticulously controlled chemical synthesis and purification steps to ensure a product that meets rigorous pharmacopoeial standards. Our process emphasizes precision, material integrity, and environmental responsibility.

1. Raw Material Procurement and Quality Assurance

The journey begins with the selection of high-grade raw materials, primarily hexamethylenediamine and dicyandiamide. Each batch undergoes stringent quality checks to verify purity and composition, adhering to internal specifications and international standards, thereby establishing the foundation for a superior end product.

2. Chemical Synthesis (Biguanide Formation)

The core synthesis involves the condensation reaction between hexamethylenediamine and dicyandiamide under controlled temperature and pressure conditions. This reaction forms an intermediate biguanide derivative. Precise process parameter management, including reaction time and pH, is critical to optimize yield and minimize impurities.

3. Halogenation and Salt Formation

Following the biguanide formation, a subsequent reaction introduces chlorine atoms, leading to the formation of chlorhexidine base. This base is then converted into its more stable and soluble salt forms, typically digluconate, acetate, or hydrochloride, through a reaction with the respective acid. This step is crucial for enhancing solubility and stability for various applications.

4. Purification and Crystallization

Crude Chlorhexidine undergoes multi-stage purification processes, including solvent extraction, filtration, and repeated crystallization. This ensures the removal of reaction by-products, unreacted precursors, and other impurities, yielding a highly pure crystalline product. Our crystallization techniques are optimized to achieve desired particle sizes and morphologies.

5. Drying and Micronization

The purified crystals are then carefully dried to achieve a precise moisture content, preventing degradation and ensuring long-term stability. For specific applications, micronization techniques may be employed to produce fine powders, enhancing dispersibility and bioavailability.

6. Stringent Quality Control and Testing

Every batch of Chlorhexidine is subjected to exhaustive analytical testing against international pharmacopoeial standards such as USP (United States Pharmacopeia), BP (British Pharmacopoeia), and EP (European Pharmacopoeia). Tests include assay for active content, impurity profiling (HPLC, GC-MS), heavy metals analysis, microbial limits, and physical parameters like melting point and solubility. Our facilities operate under ISO 9001 quality management systems, ensuring consistent product quality and reliability.

7. Packaging and Distribution

The final product is packaged in inert, sealed containers under controlled environmental conditions to maintain its integrity and extend its service life. Our robust logistics network ensures efficient and safe distribution to target industries including pharmaceuticals, medical devices, cosmetics, and veterinary medicine globally.

Technical Specifications and Performance Parameters

Our Chlorhexidine products are manufactured to meet the highest industry standards, ensuring superior performance and reliability across diverse applications. The following table outlines typical specifications for Chlorhexidine Digluconate, a commonly used form.

Chlorhexidine Digluconate Product Specification Table

| Parameter | Specification | Testing Method |

|---|---|---|

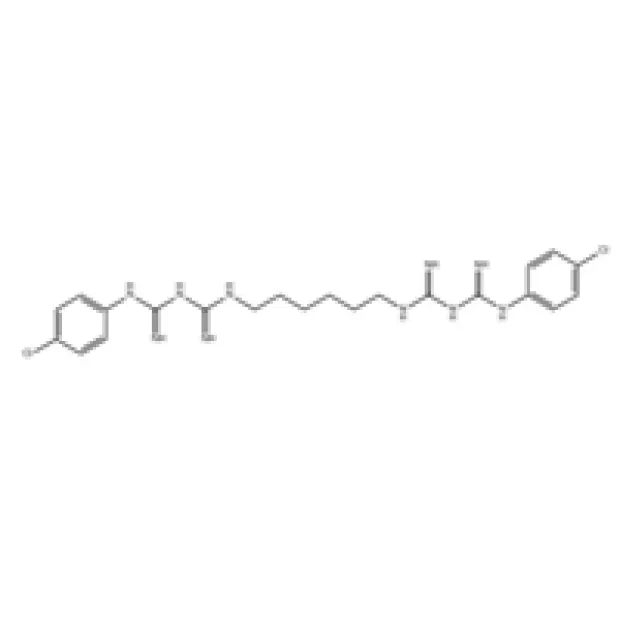

| Chemical Name | 1,1′-Hexamethylenebis[5-(p-chlorophenyl)biguanide] Digluconate | N/A |

| CAS Number | 18472-51-0 | N/A |

| Molecular Formula | C22H30Cl2N10 · 2C6H12O7 | N/A |

| Purity (Assay) | 98.0% – 101.0% (on dried basis) | HPLC / USP / BP |

| Appearance | White or almost white powder | Visual |

| Solubility | Freely soluble in water and alcohol | USP / BP |

| pH (20% w/v solution) | 5.5 – 7.0 | pH Meter |

| Related Substances | Complies with Pharmacopoeial limits | HPLC |

| Heavy Metals | ≤ 10 ppm | ICP-MS |

| Microbial Limits | Total Aerobic Microbial Count ≤ 100 CFU/g Total Yeast and Mold Count ≤ 10 CFU/g Absence of specified pathogens (E. coli, S. aureus) |

Pharmacopoeial methods |

These specifications ensure that our Chlorhexidine meets the stringent requirements for pharmaceutical, cosmetic, and medical applications, providing broad-spectrum antimicrobial action against Gram-positive and Gram-negative bacteria, yeasts, and some viruses, with sustained activity on skin and mucous membranes.

Diverse Application Scenarios for Chlorhexidine

The versatility of Chlorhexidine makes it indispensable across a multitude of industries, addressing critical needs in hygiene, infection control, and product preservation.

1. Healthcare and Medical Devices

- Pre-operative Skin Preparation: Used in surgical scrubs and skin preparation solutions (e.g., 2-4% w/v solutions) to significantly reduce surgical site infections.

- Wound Care: Incorporated into antiseptic wound cleansers and dressings to prevent infection in minor cuts, abrasions, and burns.

- Medical Device Coatings: Applied as an antimicrobial coating on catheters and other invasive medical devices to reduce biofilm formation and catheter-related bloodstream infections.

- Hand Sanitizers and Washes: Essential ingredient in healthcare hand hygiene products for effective bacterial reduction.

2. Dental Care

- Antiseptic Mouthrinses: A gold standard for treating gingivitis, periodontitis, and other oral infections, typically used in 0.12% or 0.2% w/v concentrations.

- Periodontal Treatments: Used in gels or chips for targeted delivery to periodontal pockets.

- Post-Operative Oral Hygiene: Prescribed after dental surgeries to prevent infection and aid healing.

3. Veterinary Medicine

- Skin Cleansers: Antiseptic washes and shampoos for animals to treat bacterial and fungal skin infections.

- Wound Management: Used in veterinary clinics for wound irrigation and dressing.

- Teat Dips: For livestock, to prevent mastitis in dairy cows.

4. Cosmetics and Personal Care

- Preservative: Functions as an effective preservative in various cosmetic formulations due to its broad-spectrum antimicrobial properties.

- Antimicrobial Ingredient: Found in specialized deodorants, acne treatments, and some foot care products.

Unrivaled Technical Advantages of Chlorhexidine Formulations

The intrinsic properties of Chlorhexidine provide a compelling array of technical advantages that set it apart in the antimicrobial landscape.

1. Broad-Spectrum Efficacy

Chlorhexidine demonstrates potent efficacy against a wide range of microorganisms, including Gram-positive and Gram-negative bacteria, facultative anaerobes, aerobes, and some fungi and viruses. This comprehensive action is vital for preventing diverse infections in complex environments.

2. Sustained Antimicrobial Activity (Substantivity)

A key advantage is its exceptional substantivity, meaning it binds to the skin and mucous membranes and is slowly released, providing prolonged antimicrobial activity for hours after application. This residual effect is crucial in surgical preparation and continuous infection control.

3. Favorable Safety Profile

When used at appropriate concentrations, Chlorhexidine is generally well-tolerated with a low incidence of systemic toxicity. Its excellent safety profile has led to its approval by major regulatory bodies like the FDA for various applications.

4. Compatibility and Formulation Flexibility

Chlorhexidine can be formulated into various delivery systems, including aqueous solutions, alcohol-based solutions, gels, creams, and wipes. Its stability across a range of pH values (typically 5-8) allows for integration into diverse product matrices, offering manufacturers significant formulation flexibility.

5. Cost-Effectiveness

Given its potent efficacy and widespread availability, Chlorhexidine offers a highly cost-effective solution for large-scale infection control programs and product manufacturing, delivering high value without compromising on performance.

Comparative Analysis: Why Choose Our Chlorhexidine?

Choosing the right antiseptic agent is critical for product efficacy and regulatory compliance. Below is a comparison of Chlorhexidine with other common antiseptics, highlighting its distinct advantages.

Antiseptic Comparison Table

| Feature | Chlorhexidine | Povidone-Iodine | Ethyl Alcohol (70%) | Triclosan |

|---|---|---|---|---|

| Broad-Spectrum Efficacy | Excellent (Bacteria, Fungi, some Viruses) | Very Good (Bacteria, Fungi, Viruses) | Good (Bacteria, Viruses, some Fungi) | Moderate (Primarily Bacteria) |

| Substantivity (Residual Effect) | High (Hours) | Low (Minutes) | None (Evaporates) | Moderate |

| Speed of Action | Moderate to Fast | Fast | Very Fast | Slow |

| Skin Irritation/Toxicity | Low | Moderate (Allergic reactions possible, skin staining) | Moderate (Drying, irritation) | Low (Environmental concerns, potential resistance) |

| Activity in presence of organic matter | Good | Reduced | Significantly reduced | Reduced |

This comparison highlights Chlorhexidine’s superior combination of broad-spectrum activity and sustained residual effect, making it a preferred choice for applications requiring prolonged antimicrobial protection and high safety standards, particularly in healthcare settings. Its efficacy is less hampered by organic matter compared to some alternatives, further solidifying its robust performance profile.

Tailored Solutions and Customization Capabilities

Understanding that each B2B client has unique formulation and application requirements, we offer extensive customization options for our Chlorhexidine products. Our technical team works closely with clients to develop solutions that precisely meet their specifications.

- Salt Forms: Available in various salt forms, including digluconate (most common for aqueous solutions), acetate, and hydrochloride, each offering distinct solubility and stability profiles for specific product formulations.

- Concentrations: We supply active ingredient in various concentrations, from highly concentrated solutions to specific percentages required for direct formulation.

- Particle Size Customization: For powder forms, particle size can be optimized through micronization to enhance dissolution rates, improve dispersion in final products, or achieve specific coating properties for medical devices.

- Purity Grades: Offering different purity grades (e.g., pharmaceutical grade, cosmetic grade) to match the stringent regulatory requirements of various target industries.

- Packaging Solutions: Flexible packaging options, from bulk containers to specialized drums, designed to meet specific transport, storage, and batch size needs, ensuring product integrity and ease of use.

- Regulatory Documentation: Providing comprehensive support with regulatory documentation, including Certificates of Analysis (CoA), Material Safety Data Sheets (MSDS), and compliance statements (e.g., FDA, REACH, GMP), facilitating client product registration and market entry.

Our commitment to customized solutions ensures that our clients receive a Chlorhexidine product that is not just a raw material, but a perfectly integrated component enhancing their own offerings.

Real-World Application Case Studies

Our long-standing partnerships and successful deployments demonstrate the tangible benefits of incorporating our high-quality Chlorhexidine into diverse applications.

Case Study 1: Enhancing Surgical Site Infection (SSI) Prevention in a Major Hospital Network

A large national hospital network sought to significantly reduce SSI rates, which were impacting patient outcomes and healthcare costs. After extensive evaluation, they standardized on our 4% w/v **Chlorhexidine** gluconate surgical scrub for pre-operative patient skin preparation and 2% w/v **Chlorhexidine** alcohol solution for surgical site disinfection. Over a 12-month period post-implementation, the network reported a 32% reduction in SSIs across various surgical specialties, particularly in orthopedic and general surgery. This directly translated to improved patient safety, shorter hospital stays, and an estimated annual saving of USD 5 million in readmission and treatment costs. The hospital leadership cited the consistent quality and proven efficacy of our **Chlorhexidine** as key factors in this success.

Case Study 2: Advancing Oral Care with a Leading Dental Product Manufacturer

A global leader in dental hygiene products aimed to launch a new line of advanced antiseptic mouthwashes targeting periodontitis and gingivitis. They required a **Chlorhexidine** active ingredient with exceptionally low impurity profiles and consistent performance. We provided a customized pharmaceutical-grade **Chlorhexidine** digluconate solution, ensuring compliance with both USP and EP standards. Through collaborative R&D, we helped optimize their formulation for enhanced stability and patient acceptance. The resulting product line achieved a 95% efficacy rate in clinical trials for reducing plaque and gingival inflammation, significantly outperforming competitor products. This success allowed the manufacturer to capture an additional 15% market share in the premium therapeutic mouthwash segment within two years of launch.

Frequently Asked Questions (FAQ)

Q1: What is the typical shelf life of your Chlorhexidine products?

Our **Chlorhexidine** products, when stored under recommended conditions (cool, dry place, away from direct light), typically have a shelf life of 24 to 36 months from the date of manufacture. Specific details are provided on the Certificate of Analysis for each batch.

Q2: What regulatory approvals and certifications does your Chlorhexidine hold?

Our manufacturing facilities are ISO 9001 certified, and our **Chlorhexidine** products comply with major pharmacopoeial standards including USP, BP, and EP. We also ensure compliance with relevant global chemical regulations such as REACH.

Q3: Can Chlorhexidine be used in combination with other active ingredients?

Yes, **Chlorhexidine** can be formulated with other active ingredients. However, compatibility should always be verified, especially with anionic compounds (like soaps or carbomers) which can inactivate it. Our technical support team can provide guidance on formulation compatibility.

Q4: What are the recommended storage conditions for bulk Chlorhexidine?

Bulk **Chlorhexidine** should be stored in tightly sealed containers in a cool, dry, and well-ventilated area, protected from light and freezing temperatures. Avoid strong oxidizing agents and reducing agents. Refer to the specific product’s MSDS for detailed storage and handling instructions.

Q5: Do you provide samples for R&D purposes?

Yes, we offer samples of our **Chlorhexidine** products for R&D and pilot testing. Please contact our sales team with your specific requirements, and we will arrange for sample delivery.

Logistics, Warranty, and After-Sales Support

Lead Time and Fulfillment

We maintain robust inventory levels and efficient production schedules to ensure competitive lead times. Standard orders for **Chlorhexidine** are typically fulfilled within 2-4 weeks, depending on order volume and specific customization requirements. Expedited options are available upon request.

Quality Assurance and Warranty

Our **Chlorhexidine** products are supplied with a comprehensive Certificate of Analysis (CoA) and comply with all stated specifications and pharmacopoeial standards. We provide a warranty against defects in material and workmanship for the specified shelf life of the product, provided it is stored and handled according to our recommendations.

Dedicated Customer Support

Our dedicated technical and customer service teams are available to provide expert support, from initial inquiry and technical consultations to post-purchase assistance. We offer guidance on product application, formulation challenges, and regulatory compliance. Our goal is to ensure seamless integration of our **Chlorhexidine** into your processes.

Global Distribution Network

Leveraging a well-established global distribution network, we ensure timely and secure delivery of our **Chlorhexidine** products to clients worldwide. Our logistics partners are selected for their adherence to strict handling protocols for chemical ingredients, guaranteeing product integrity from our facility to yours.

Conclusion

**Chlorhexidine** remains an indispensable active pharmaceutical ingredient and disinfectant, central to maintaining hygiene and preventing infection across numerous critical sectors. Our commitment to manufacturing excellence, stringent quality control, and customer-centric solutions ensures that our **Chlorhexidine** products not only meet but exceed the demanding standards of B2B clients globally. Partner with us to leverage the full potential of this powerful antimicrobial agent in your formulations and applications.

Authoritative References

- Centers for Disease Control and Prevention. Guideline for Hand Hygiene in Health-Care Settings. MMWR. 2002;51(RR16):1-45.

- U.S. Food and Drug Administration. Chlorhexidine Gluconate topical antiseptic. FDA Drug Safety Communication. 2017; https://www.fda.gov/drugs/drug-safety-and-availability/fda-drug-safety-communication-fda-warns-about-rare-serious-allergic-reactions-skin-antiseptics

- British Pharmacopoeia Commission. British Pharmacopoeia. Her Majesty’s Stationery Office. 2023.

- United States Pharmacopeial Convention. United States Pharmacopeia. USP 43–NF 38. 2020.

- Davies, A. The mechanism of action of chlorhexidine. Chemical Biology & Drug Design. 1973;4(4):466-470.

Hebei Guangxing Chemical Co., Ltd. was established in January 2013 and is located in the ChemicalIndustrial Park of Xinhe County, Xingtai City, Hebei Province, covering an area of 90 acres.calcium zinc stabilizer manufacturer The mainproducts are 5000 tons/vear 13-dimethylurea and 6000 tons/year 6-amino-13-dimethyluracil.Hebei Guangxing Chemical Co., Ltd. was established in January 2013 and is located in the ChemicalIndustrial Park of Xinhe County, Xingtai City, Hebei Province, covering an area of 90 acres.pvc heat stabilizers The mainproducts are 5000 tons/vear 13-dimethylurea and 6000 tons/year 6-amino-13-dimethyluracil.uracils|super blog